integrated with existing IT infrastructure and production systems.

We take care of the design of our machines from a mechanical, electrical, fluidic and software point of view, implementing the best programming language based on the type of applications and then developing them based on project’s requirements using: PLC, PC, LabView, Robot.

We have the habit of establishing a close collaboration with our customers right from the first design stages, in order to fully understand their real needs and analyzing the various problems, being able to propose the right solutions.

FSC Project provide a design service aimed at fully satisfying the needs of each customer, who will be able to see his own idea evolve and grow from the design phase to the commissioning of the machines.

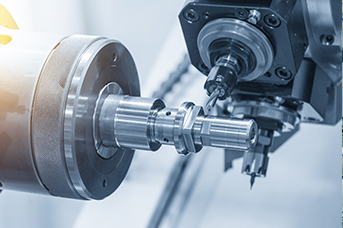

We build all mechanical parts (turning, milling, carpentry) related to the construction of the designed machines.

We assemble the mechanical, hydraulic, pneumatic and electrical parts of each machine, checking each design phase that ends with the upload of the software, specifically developed for the required application.

We proceed then to the delicate machine’s set-up and tuning phase, where is tested the communication between all the devices integrated in the system, then we proceed to debug the final operating cycle in order to ensure the fulfillment of the specifications required.

Our machines are fully tested in all their functionality before being delivered to the customer, in order to ensure and certify the compliance with the scope of supply and reduce the time that passes between the first commissioning and the actual production launch.

The team dedicated to machines installation will take care of the tasks necessary for the re-ignition of the machine and the subsequent commissioning, checking again all the functionalities in order to ensure that during the transport, the equipment has not been damaged and thus guaranteeing the quick use of the machine for production launch.

Assistance service provided by dedicated technical staff able to perform any type of assistance/maintenance required by the machinery.

Supply of spare parts always ready for shipment.

- Phone

- Address

REGISTERED OFFICEOPERATIONAL HQ